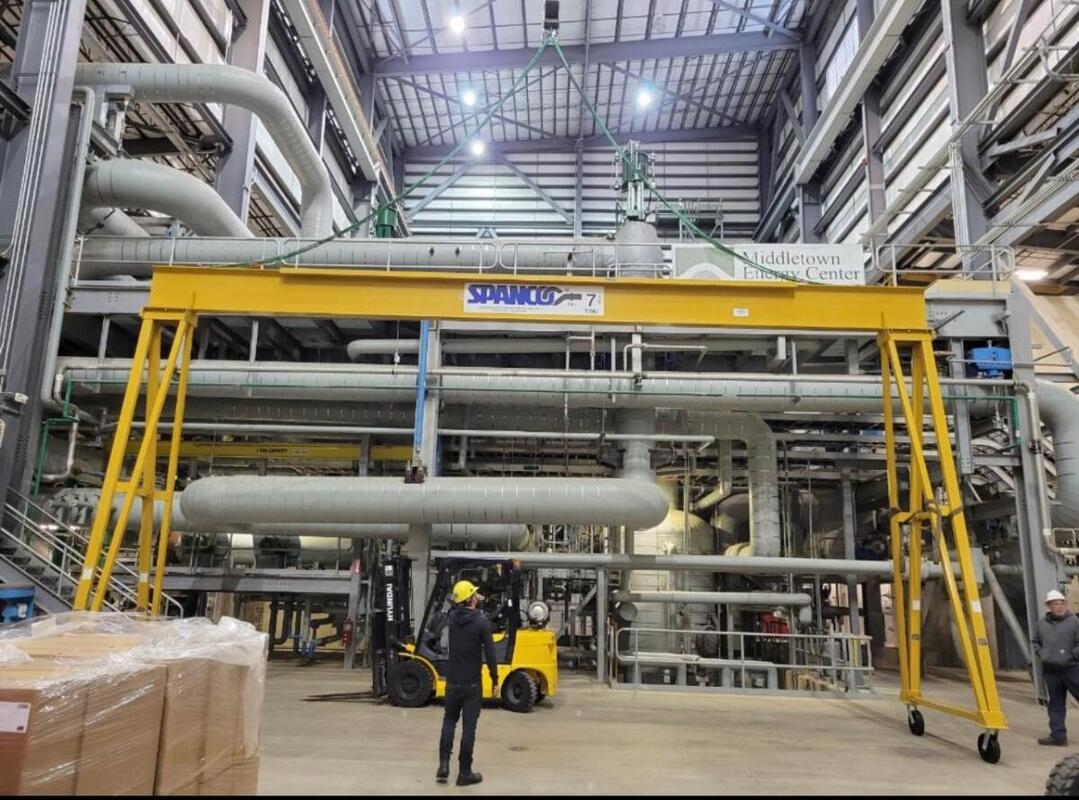

Overhead cranes and hoists are essential pieces of machinery in many industrial settings. However, if not properly maintained and inspected, they can pose a serious safety hazard in the workplace. According to the U.S. Occupational Safety and Health Administration (OSHA), there are nearly 100 crane-related fatalities each year and countless injuries. In this blog, we will explore the importance of inspections and maintenance in preventing such devastating incidents. We will also introduce American Industrial Repair, a company that provides inspections, maintenance, sales, and repair to overhead cranes and hoists.

How Can I Keep My Employees Safe Around Overhead Cranes & Hoists?

Inspections and maintenance are crucial in preventing fatalities and injuries related to overhead cranes and hoists. OSHA requires that overhead cranes and hoists be inspected at regular intervals to ensure that they are functioning properly and safely. Regular inspections can identify potential issues such as worn-out parts, faulty wiring, and corrosion. Fixing these issues before they become major problems can prevent accidents from occurring. This is where American Industrial Repair comes in.

Who Can Inspect My Overhead Cranes?

American Industrial Repair provides inspections, maintenance, sales, and repair services to overhead cranes and hoists. Their OSHA inspections start at $80 per crane and can help identify potential safety hazards. Regular maintenance can prevent accidents and downtime by keeping machinery in good working condition. The company's highly trained technicians can perform repairs quickly and effectively to prevent injuries and fatalities.

Knowledge Is Power: Overhead Crane Safety Training w/ AIR

In addition to inspections and maintenance, American Industrial Repair also provides safety training for employees. This training can help employees identify potential hazards and understand how to properly operate cranes and hoists safely. Proper training can prevent accidents and ensure that employees are following OSHA regulations.

American Industrial Repair: Your Premier Overhead Crane & Hoist Safety Resource

American Industrial Repair serves the Cincinnati area, as well as Louisville, Indianapolis, Lexington, Dayton, Columbus, and more. They have over 40 years of experience in the industry and are committed to providing exceptional service and quality work. Even with regular inspections and maintenance, accidents can still occur. However, having a reliable and experienced company like American Industrial Repair can make all the difference. Their quick response times and dedication to safety can prevent accidents from becoming tragedies.

Conclusion:

Overhead cranes and hoists are essential pieces of machinery in many industrial settings. However, they can be dangerous if not properly maintained and inspected. Regular inspections and maintenance can prevent accidents from occurring and save lives. American Industrial Repair is a reputable company that provides inspections, maintenance, sales, and repair services to overhead cranes and hoists. Their commitment to safety and exceptional service can give employers peace of mind knowing that their workers and equipment are safe. Remember, safety is everyone's responsibility in the workplace.